About us

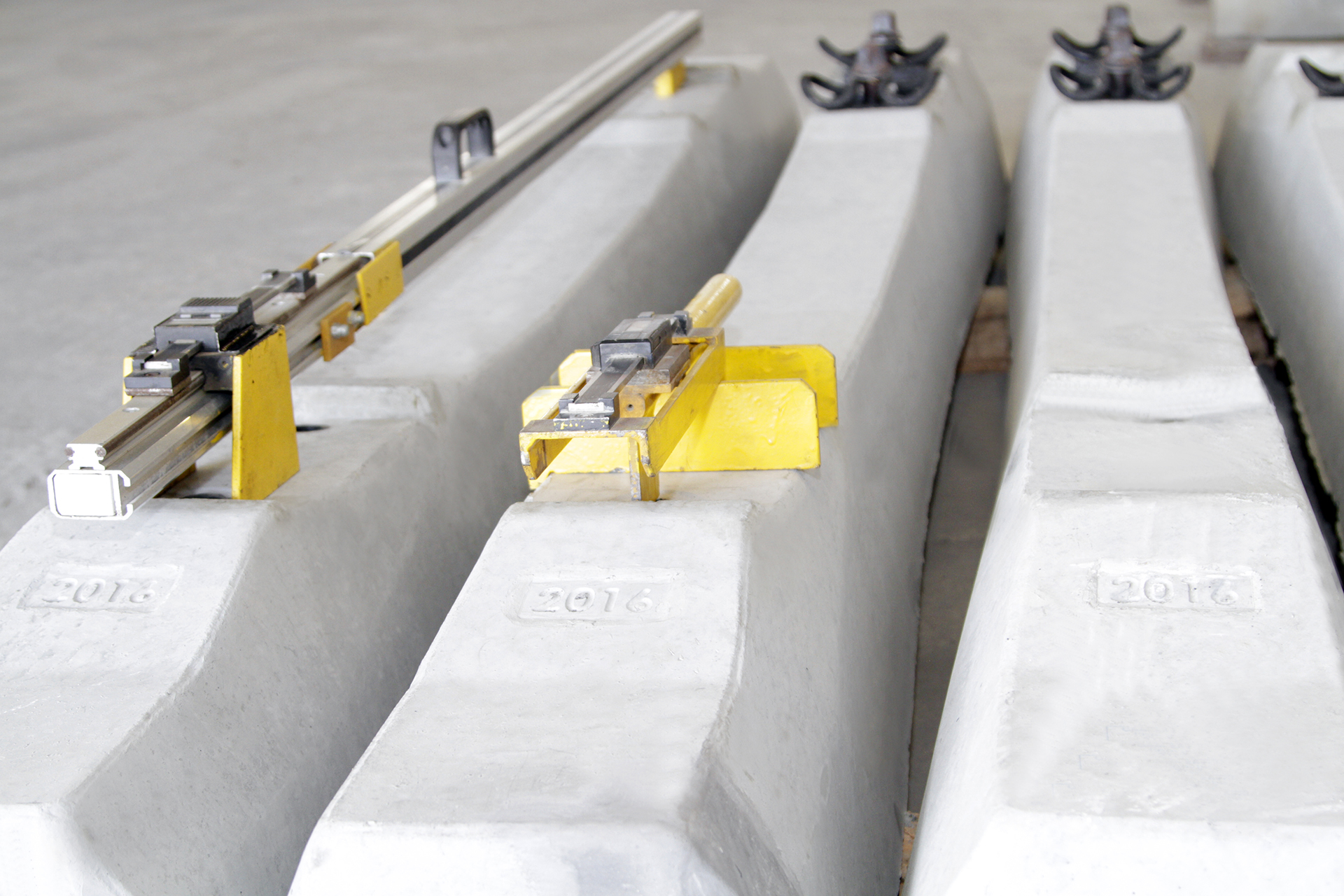

Concrete Sleeper Factory “Şpal Zavod”, was founded in 2005 and started its production since 2006. The total territory of the factory is 62 240 square meters from which 2904 square meters is being used for manufacturing. The factory is located in Alyat village, Garadag area, Azerbaijan. At “Şpal Zavod” there are two types of sleeper productions:

- Concrete sleeper type B70

- Concrete turnout bearers

By having approximately 200 workers, annual productive capacity of concrete manufacture is 511 000 standard sleepers and 120 sets of Concrete turnout bearers in a year. It means provision of sleepers for about 270 km new railway construction. The materials which are being used for the sleeper are local except the high tensile steels which are gathered from Germany. Fasteners which are being used on concrete sleepers are System W21 which are being purchased from German company “Vossloh”. The production samples of “Şpal Zavod” have been tested successfully by German laboratory “Bautest GmbH”, and meet all the requirements of concrete sleeper production.

Concrete sleeper type B70

Concrete sleeper type B70 is being of flexibility, is produced in accordance with the standards of EN 13230-2 and EN 13230-1.

Technical specification: Sizes:

| Speed: | 230 km/s | Length of sleepers: | 2700 mm | |

| Weight without fastening: | 309 kg | Max. width: | 300 mm | |

| Weight with fastening: | 315 kg | Height under rail: | 214 mm | |

| Fastening systems: | Vossloh – W21 | Width of railway channel: | 1520 mm | |

| Frost-resistance | F200 | Railway type: | R65 | |

| Cement brand, kgQ/sm3 | 500 |

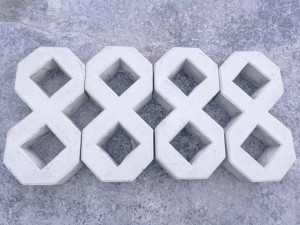

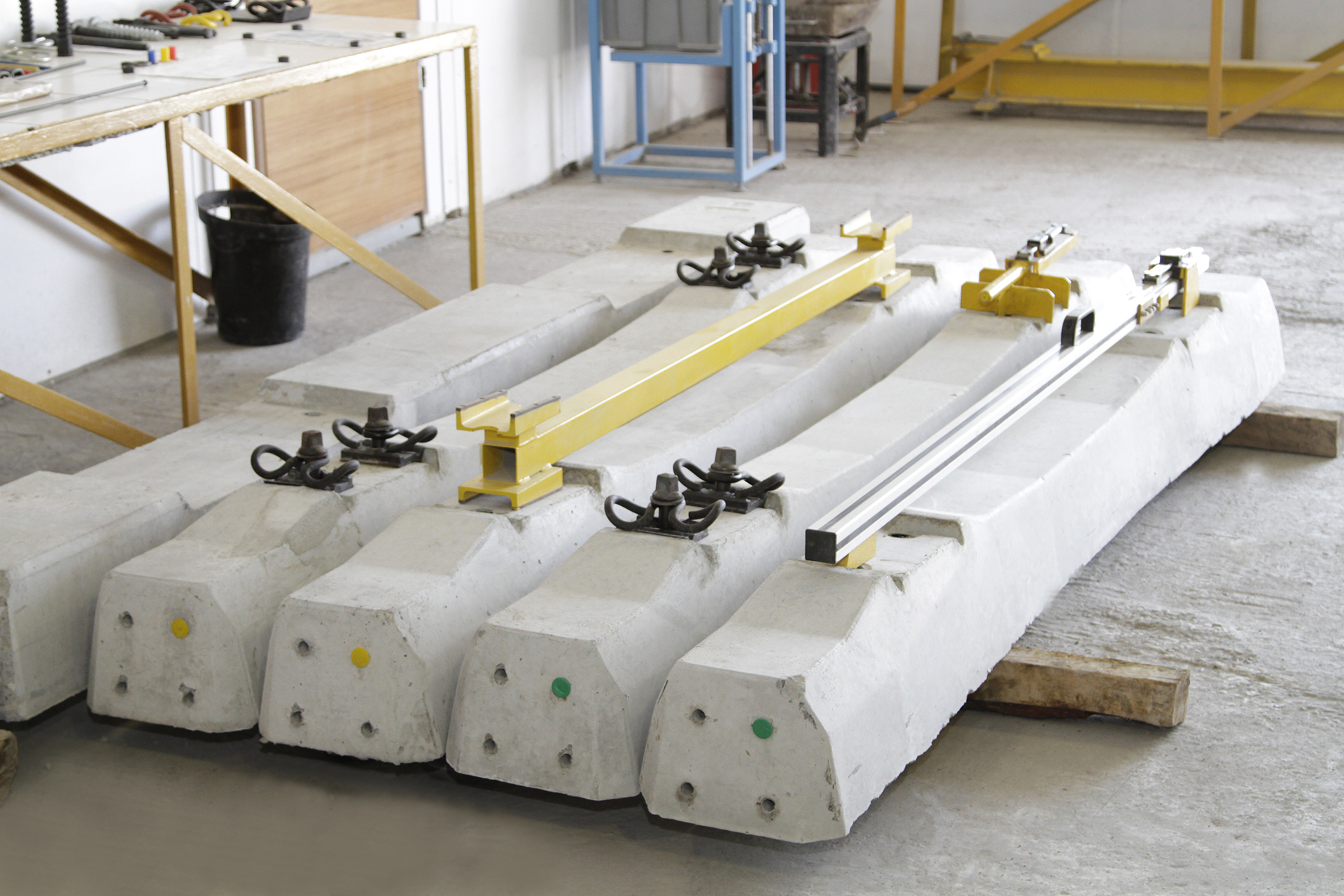

Concrete turnout bearers

Concrete turnout bearers sleepers are used in crossing railway and produced in various sizes.

Technical specification and sizes:

| Cement brand, kgQ/sm3 | 500 |

| Frost-resistance | F200 |

| Fastening systems: | Vossloh – W21 |

| Length (min): | 2700 mm |

| Length (max): | 5400 mm |

| Max. width: | 300 mm |

| Height: | 220 mm |

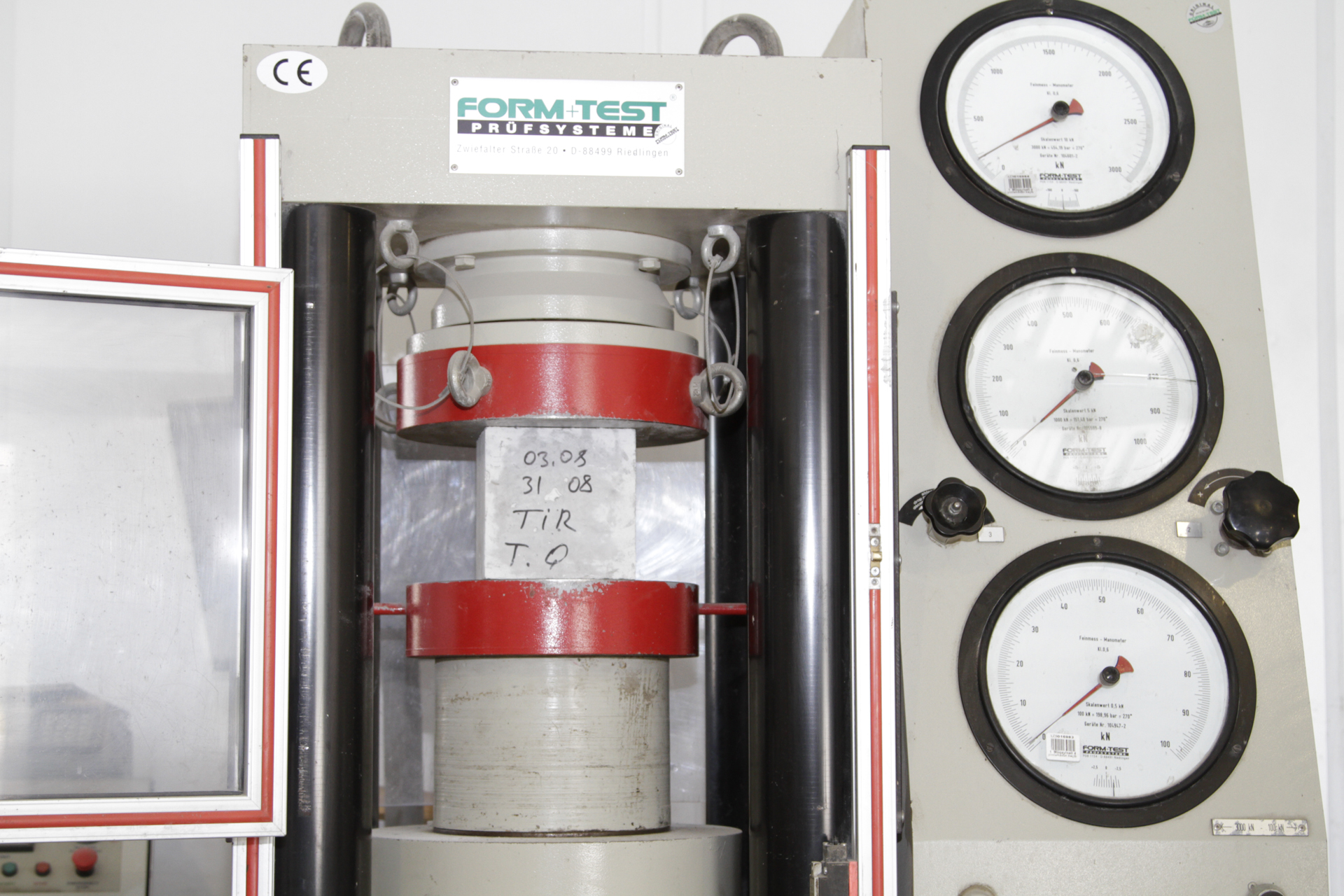

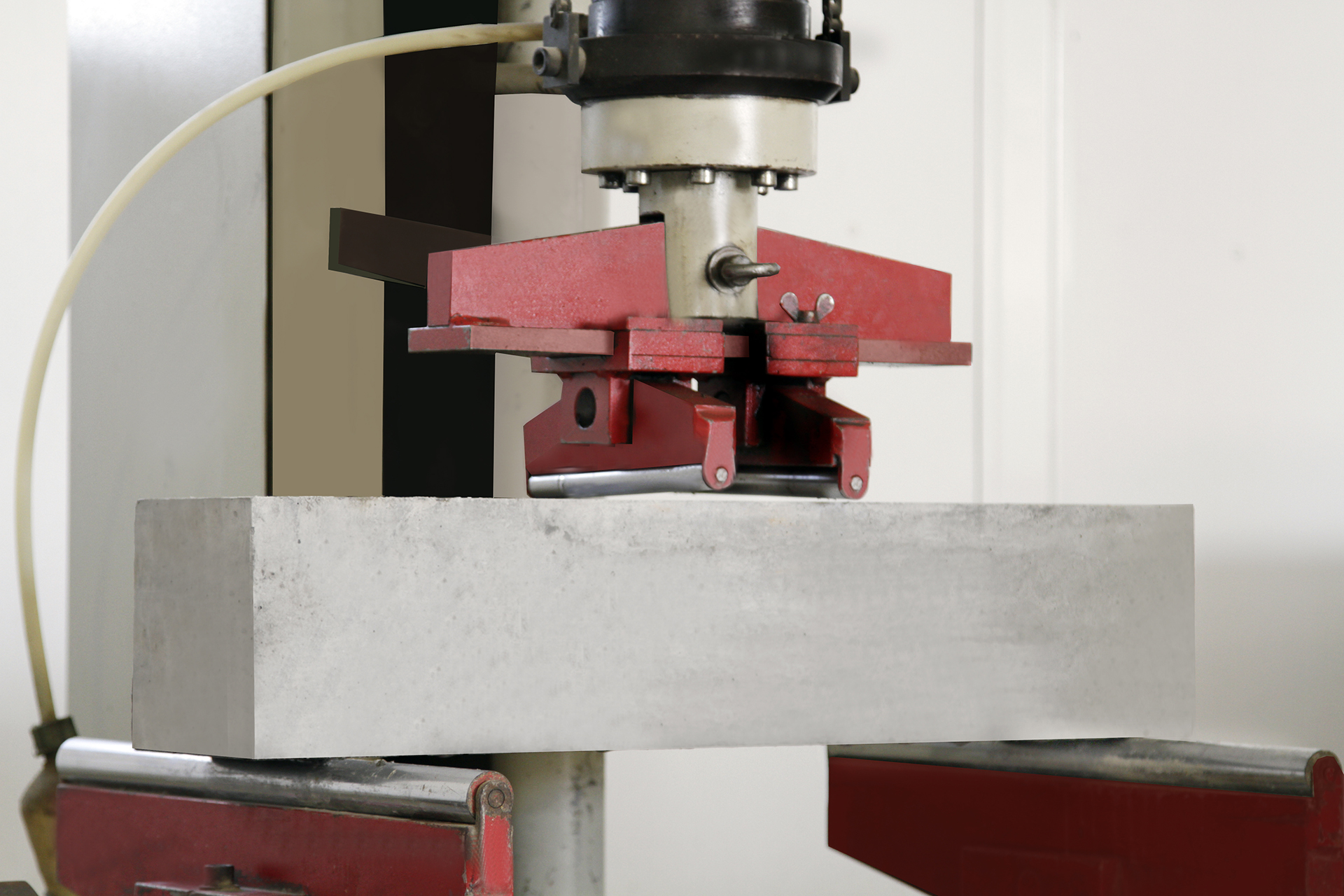

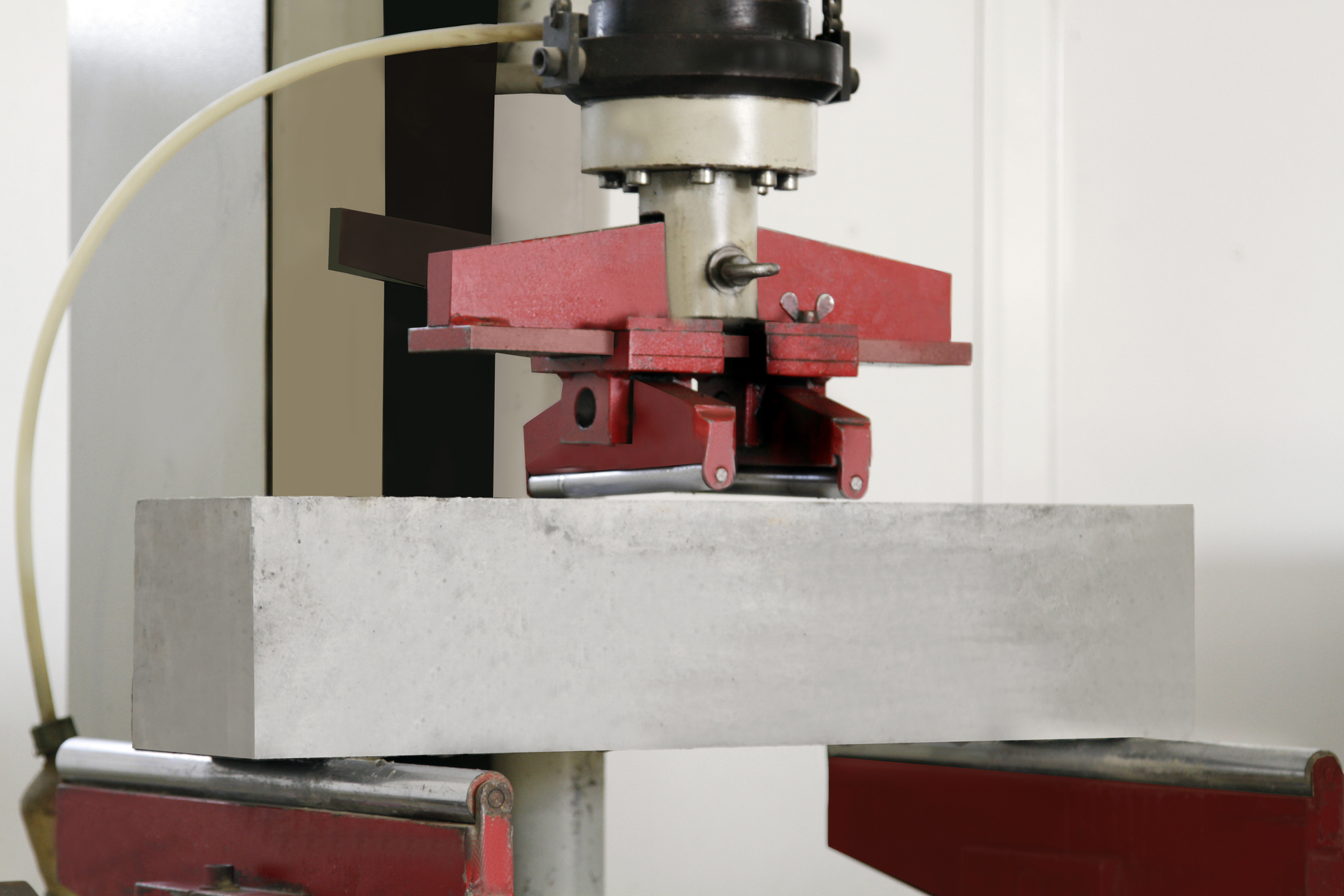

Laboratory

Central laboratory has provided with contemporary facilities of European production. Experiments and analyses in laboratory carried out in line with Azerbaijan Republic State Standard and International Standards (İSO, ASTM, QOST) by experienced specialists. Our laboratory is one of the specialized laboratories where concrete and concrete materials of the country are tested. Necessary raw materials considered for production and products made of raw materials are tested in our laboratory. Testing of product and raw material is performed in several times in a day.

Projects

Completed and ongoing projects:

- Construction of “Gazakh Sement” railway - 2013

- Construction of “Alat-Liman” railway - 2014

- Construction of “Baku – Sumgayit” interurban high-speed rail - 2015

- Construction of “Baku – Boyuk Kasik” Railway (ongoing)

- Southern Railway (Project)

HSE policy

We take care of our employees!

The implementation of HSE (Health, Security and Environment) principles is integral part of our business. Behind the use of world standards in HSE policy stands the goal of minimize the accidents in the production process. We believe any industrial accident can be prevented in advance. Our main goal is to take care of our employees and to ensure their safety.

Career

Staff policy of "Speeler Plant" is carried out by Management of Human Resources Department. One of the most important issues for the company is its staff. Thus, personnel selection and promotion of staff’s performance, also to increase their professionalism is implemented by proper department as the main principle of company’s staff policy. Equal conditions are created for everyone to be the part of the company regardless of their gender, race, religion, nationality and social status. Any person meeting the requirements of the vacancy may be an employee of “Speeler Plant” through an interview.

Contact

| Az 1081, Settlement Elet, Azerbaijan | Sales representative: | |

|

Phone: +994 12 499 01 13 Mob: +994 55 400 82 82 |

sales@bakushpal.az | |

| info@bakushpal.az |

.jpeg)

.jpeg)